Types of Carbon Fiber Wraps

Carbon fiber wraps come in various types and structures, each unique and capable of significantly transforming the appearance of your car. Understanding the differences between these types can help you choose the ideal carbon fiber based on your preferences and needs.

Glossy Carbon Fiber Wrap

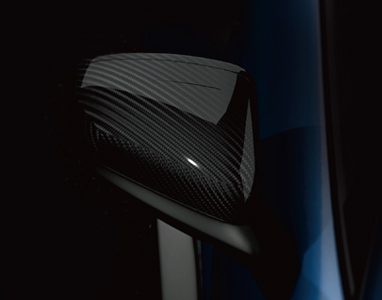

The glossy carbon fiber wrap has a high gloss, enhancing the depth and texture of the carbon braided pattern. It is ideal for car owners seeking a bold and modern look. It can reflect light and highlight the body contour, making it look more dynamic. Especially under sunlight or artificial lighting. It is usually more suitable for the hood, roof, and partial tiling.

Matte Carbon Fiber Wrap

The matte carbon fiber wrap is more understated and everyday. It retains the complex braided texture of carbon fiber but has no reflective surface. Matte packaging is usually more suitable for an invisible or sturdy appearance and works well throughout the entire vehicle body and selected components. This type is very popular among enthusiasts who want to avoid the glitz of luster while still enjoying the aesthetic of carbon fiber technology.

Textured / Forged Carbon Wrap

Textured or forged carbon wrap presents a unique variation inspired by real forged carbon fiber material, which has a randomized, marbled structure instead of the uniform weave seen in traditional carbon. This finish creates a distinct, luxury-inspired effect and is often used in high-end automotive interiors or exclusive body accents. Forged carbon wrap stands out for its artistic, irregular pattern and adds a premium touch to any application.

3D, 4D, 5D, and 6D carbon fiber wraps

The 3D, 4D, 5D, and 6D carbon fiber wraps refer to different levels of visual depth and realism. A 3D wrap offers a basic embossed texture that simulates the weave but without reflective qualities. 4D adds a slight gloss and a more lifelike appearance. 5D enhances this further with ultra-gloss finishes that make the wrap look even closer to real carbon fiber. 6D is the most advanced, delivering deep, mirror-like shine with multi-layered realism that responds to light and movement.

Carbon Fiber Wrap vs. Traditional Paint

When comparing carbon fiber wrap to traditional paint, it’s important to look beyond the surface. While both serve to enhance your car’s appearance, they differ significantly in terms of durability, cost, flexibility, and long-term impact on resale value.

Durability and Maintenance

Carbon fiber wraps, especially those made with high-quality TPU, offer excellent durability and self-repairing capacity.

Traditional automotive paint is more susceptible to chips, fading, oxidation, and staining. To maintain a painted surface, regular waxing and polishing are usually required. It’s more vulnerable to long-term wear, especially in harsh climates or with daily use.

Cost Differences

Traditional paint can be significantly more expensive than wrapping your vehicle in carbon fiber film. A professional-quality paint job often ranges from hundreds to several thousands of dollars, depending on the complexity, materials, and labor involved.

Carbon fiber wraps are more budget-friendly and allow for high-impact customization without the high price tag. You can also wrap specific parts rather than the entire vehicle, which adds even more cost efficiency.

Customization Flexibility

Carbon fiber wraps provide unmatched flexibility in customization. Whether you want to accent specific parts like the hood, roof, or interior panels, or fully wrap the entire vehicle, wraps offer a wide range of finishes, glossy, matte, forged, and various 3D/4D/5D textures.

Traditional paint requires much more time and commitment to alter. Any changes or corrections to a painted surface typically require sanding, re-priming, and repainting, making the process time-consuming and irreversible once applied.

Reversibility and Resale Value

One of the biggest advantages of a carbon fiber wrap is that it’s reversible. If your preferences change or if you’re preparing to sell the vehicle, the wrap can be safely removed without damaging the original paint underneath, provided the installation was done properly.

Traditional paint is permanent, and any scratches, fading, or personalization choices may lower the resale value.

How to Choose the Right Carbon Fiber Wrap

Selecting the right carbon fiber wrap requires more than just picking a finish you like. To ensure a clean installation, long-lasting results, and the visual impact you’re aiming for, you need to consider your vehicle’s shape, your budget, and whether you’re doing it yourself or hiring a professional.

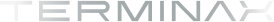

Based on the Car Model and Curves

The shape and complexity of your vehicle’s body panels play a major role in wrap selection. Sports cars or luxury sedans require wraps with greater flexibility and conformability.

Vehicle with simpler geometry, such as a boxy SUV or hatchback, more rigid PVC wraps may still work effectively. Always evaluate the surface area and complexity before choosing a wrap type, especially if you’re planning a full-body application.

Budget and Material Quality

Carbon fiber wraps come in a wide range of price points, and it’s important to balance cost with expected performance. Cheaper wraps are often made from low-grade materials that fade, crack, or peel over time. Investing in a mid-to-premium wrap, particularly one made with TPU and UV-resistant top coats, ensures longer life, better resistance to environmental damage, and a more realistic carbon texture.

If your budget is limited, consider using higher-end wraps for visible or high-impact areas, and lower-cost options for less noticeable zones like roof undersides or interior panels.

Professional Installation vs. DIY Kits

Whether you go with a professional installer or apply the wrap yourself depends on your skill level, the complexity of your car’s body, and the material you’ve selected.

Professional installation guarantees a cleaner finish, especially around complex surfaces, edges, and seams. Experts also know how to properly stretch, heat, and seal the wrap to avoid bubbles or lifting.

If you’re wrapping flat or simple areas like mirrors or interior trim and you’re confident with hands-on work, DIY can be a rewarding and cost-saving option. Just be sure to follow all prep and application guidelines closely.

Choosing the right carbon fiber wrap is about aligning your expectations with your vehicle’s needs, your budget, and your level of experience. Thoughtful planning ensures a smooth application and a finish that elevates your car’s appearance for years to come.

Installation and Maintenance

For your carbon fiber wrap to perform, last, and look its best, proper installation and upkeep are essential. Knowing what to anticipate and how to take care of the wrap afterward can significantly increase its lifespan and maintain the best possible appearance for your car, whether you’re applying it yourself or with the help of a professional.

Installation Tips and Precautions

Before installation, please read the following requirements carefully:

- Wax, oil, dirt, and debris must all be removed from the vehicle’s surface. The wrap may not adhere correctly due to even the smallest impurities.

- Installing a dust-free, indoor space with regulated temperatures between 15 and 25°C (60 and 77°F) is ideal.

- Use high-quality equipment, such as precision cutting blades, heat guns, and felt-edged squeegees, if you’re doing the installation yourself.

- The carbon pattern can be distorted and adhesion weakened if the material is overstretched, particularly on sharp corners.

Maintenance Best Practices

Although it takes some attention, maintaining a carbon fiber wrap is comparatively easy:

- Automatic car washes can cause peeling or scratching, so hand washing is preferable.

- To gently clean the surface, use soft microfiber cloths and a pH-neutral soap.

- Steer clear of harsh chemicals like solvents or petroleum-based cleaners, as well as abrasive pads.

- For glossy finishes, you can add a ceramic coating or vinyl-safe spray sealant to improve shine and shield against water stains and UV rays.

- Steer clear of wax-based products that might leave residue or streaks on matte or textured wraps.

- Examine edges and high-impact areas frequently for indications of lifting or damage, and take quick action to stop problems from getting worse.

Lifespan and When to Replace

A high-quality carbon fiber wrap should last four to seven years on average, depending on weather, sunlight exposure, and maintenance.

Fading, bubbling, edge lifting, or obvious wear in high-contact areas are indicators that the wrap needs to be replaced.

How to Remove the Wrap Safely

When the time comes to remove the wrap, whether for replacement or resale. It’s essential to do it correctly to avoid damaging the paint underneath.

- We recommend using a heat gun to soften the vinyl’s adhesive, then slowly peel the wrap back at a 45° angle.

- To avoid leaving adhesive residue or scratching the surface, do not remove it cold or with sharp instruments.

- An adhesive remover or solvent that is safe for vinyl can be used to get rid of any leftover glue.

- The original paint should be in superb condition after removal if the wrap was applied and maintained correctly, protecting the value of your car when you sell it.

TERMINAX Carbon-X™ Fiber PPF’s Superiority

Carbon fiber car wrap has a unique carbon fiber texture, which can significantly improve the appearance of the vehicle texture and meet the needs of personalized modification. At the same time, the film can provide additional protection for the original car paint in daily use, prevent the aging of the paint caused by ultraviolet radiation, and avoid damage caused by minor scratches and acid rain erosion.

Additionally, carbon fiber car wrap offers exceptional durability and easy maintenance. Made from high-quality TPU material, they resist fading, provide strong oxidation resistance, and adapt well to various climate conditions. The film’s surface is water-resistant and anti-fouling, preventing dust and dirt from adhering easily. Daily cleaning is as simple as wiping with clean water or a ordinary car wash, with no additional use of special cleaners.

From a comprehensive point of view, carbon fiber car wrap is an economical, practical, and cost-effective way of modification, which can effectively protect the car paint while meeting individual needs of the owner. Whichever way you look at it, it is a choice worth considering.